As metal sheds become a more popular way to store household items, or even create extra living space outdoors, it’s important to make sure they’re correctly insulated. After all, an outdoor shed can get really hot in summer and very cold during winter if it isn’t properly sealed against the elements of nature! Fortunately, insulating your metal shed doesn’t have to be difficult – all you need is some basic DIY skills and this guide on how to insulate your structure and maximize its protective benefits. Read on for our top tips on everything you’ll need to achieve maximum insulation in any climate.

Whether Or Not Metal Shed Insulation Is Needed?

When deciding whether your metal shed needs insulation, it is important to consider the climate in which you live, the use of your shed and how much time you plan on spending in the shed. In especially cold climates, insulation can help protect stored items from extreme temperatures and moisture, while also providing an extra layer of soundproofing. If you’re planning to spend a lot of time working or entertaining friends in the shed all year long, then insulating your metal shed will make it more comfortable during colder months.

Furthermore, adding insulation can even increase property value due to its effectiveness at keeping out noise and rain.

Fortunately, installing insulation to a metal shed is fairly simple and can be done as a DIY project. It’s important to choose the right materials for your climate and application, as well as use proper safety measures when working with hazardous chemicals or equipment. With the right preparation, tools and know-how, you can easily insulate your metal shed on your own in an afternoon. [1]

How Does Metal Building Insulation Work?

Insulation helps to regulate the temperature inside a metal shed by trapping air within its fibers. This trapped air acts as an insulating barrier between the outside and inside of the shed, reducing heat transfer and keeping temperatures more comfortable and consistent. Metal building insulation works in much the same way as any other type of insulation. It is installed within wall cavities or under roofing, where it provides a barrier against air movement.

In order for metal building insulation to work most effectively, it is important to consider the type of material and its R-value. The higher the R-value, the more effective the insulation will be at keeping temperatures regulated inside a metal shed. Different types of materials have different R-values, so you should select one that is suited to your needs. Additionally, it’s important to consider how well the insulation is installed. Poorly fitted insulation may create gaps that allow heat transfer and reduce efficiency. Therefore, when installing insulation in a metal shed, it’s best to hire a professional who has experience with this type of work. [2]

Reasons for Insulating a Metal Shed

Condensation

Insulating a metal shed can help to eliminate condensation build up on the walls. This is especially true during the colder months when air inside the shed is warmer than outside. By adding insulation, you will be able to keep an even temperature throughout the interior and reduce moisture build up.

Heat loss

In colder climates, it’s important to insulate your metal shed in order to prevent heat from escaping through its walls. This can help keep temperatures within the shed at a comfortable level, as well as helping conserve energy and reducing your own heating bills too!

Noise reduction

A metal shed is more prone to reverberating sound, which can make it quite noisy inside if not insulated correctly. Adding insulation will help absorb and reduce sound within the shed, making it a more pleasant place to be.

Protection from extreme temperatures

Insulating your metal shed will also provide protection from extreme temperatures. This can be helpful in hot climates where an insulated shed can stay cooler than its un-insulated counterpart, as well as helping keep the inside of the shed free of frost and snow in cold climates.

By adding insulation to your metal shed, you’re not only providing yourself with a comfortable environment but also preventing condensation build up, reducing noise levels and preserving energy too! The long-term benefits are definitely worth the effort and expense involved, so why not get started today? [3]

Insulation Options for a Metal Shed

Fiberglass Batts

Fiberglass batts are one of the most common methods of insulating a metal shed. The process involves cutting rolls of fiberglass insulation to fit between the studs or wall joists and then taping them in place. This type of insulation has an R-value of around 2.5 per inch, which means it is relatively inexpensive and easy to install.

Spray Foam

Another popular option for insulating a metal shed is spray foam. Spray foam expands when it comes into contact with air, creating an airtight seal that helps keep out drafts and moisture. Spray foam insulation is more expensive than other materials but provides superior performance, with an R-value up to 7 per inch. It can also be used to seal any holes or cracks in the shed walls, making it an ideal choice for older structures.

Foam Board Insulation

Foam board insulation is another option that can be used to insulate a metal shed. This type of insulation consists of rigid foam panels with a protective outer coating. It provides excellent thermal performance, with an R-value up to 10 per inch, and can be easily cut to fit around joists and other obstructions. Foam board insulation is also relatively inexpensive and easy to install, so it’s a great choice for DIYers on a budget.

Reflective Sheeting

Reflective sheeting is another great way to insulate a metal shed. This material reflects heat away from the shed, helping to keep it cool during hot summer days. Reflective sheeting is usually installed directly on the roof and walls of the shed, and is available in a variety of colors and finishes. It has an R-value of 1 per inch, so while it won’t provide much thermal protection, it can help reduce heating costs by reflecting heat away from your building. [4]

Insulating paint

If you’re looking for a more affordable option, you may want to consider insulating paint. This type of paint has been designed specifically to insulate metal surfaces and can be applied with a brush or roller. Insulating paint provides an R-value of around 2 per inch and can help reduce noise, as well as reduce heat transfer. While it won’t provide the same level of protection as other materials, it is a choice for those on a budget.

Mineral Wool

Mineral wool is another option for insulating a metal shed. This type of insulation consists of strands of glass fiber or rock that have been treated with a special binder that makes them fire-resistant. Mineral wool provides an R-value of 3 to 4 per inch and can be easily cut to fit around joists and other obstructions. It also has excellent acoustic performance, making it a great choice for soundproofing a shed.

Blown-in Cellulose

Blown-in cellulose insulation is a great way to insulate a metal shed. This type of insulation consists of fine particles of recycled paper or wood that are blown into the walls using specialized equipment. Blown-in cellulose provides an R-value of around 3 per inch and can be used in both new and existing structures. It also has excellent soundproofing qualities, making it ideal for sheds located near roads or busy areas. [5]

No matter what type of insulation you choose, make sure to take your time and do the job correctly. Properly insulated metal sheds can help you save money on energy bills in the long run, so it’s worth the effort! Be sure to check with local building codes before starting your project to ensure that you are in compliance with regulations.

The Best Option for Insulating Metal Sheds

When it comes to insulating a metal shed, the best option is foam board insulation. This type of insulation is lightweight and easy to install, making it the perfect choice for many types of sheds. It also provides excellent thermal resistance and can be used in both hot and cold climates.

When installing foam board insulation, it is important to use the correct materials and techniques. Make sure that all seams are properly sealed with foil tape to prevent air infiltration, and use a caulking gun around window frames and other openings for a secure seal. Additionally, you should also check for any gaps between panels or around doors that could cause air leakage or water damage. For added protection against moisture, consider applying a vapor barrier to the interior of your shed walls before installing insulation.

Foam board insulation is easy to install yourself with basic tools and materials – so if you’re looking for an effective way to keep your metal shed comfortable all year round, look no further than this trusty solution! [6]

How to Insulate a Metal Shed: Easy Tips and Tricks

Insulating your metal shed is a great way to keep the temperature inside comfortable, no matter what the season. It can also help cut down on energy costs since it will better retain heat in winter and cool air in summer. Here are some easy tips and tricks for properly insulating your metal shed:

- Choose suitable insulation material – There are several materials available that you can use to insulate a metal shed, such as fiberglass batts, rigid foam boards, or spray foam insulation. Consider factors like R-value (resistance to heat flow), moisture control, fire protection, and cost before making your choice.

- Measure accurately – Take accurate measurements of the area you need to insulate before you purchase materials. This will help ensure you buy enough without wasting money on extra material.

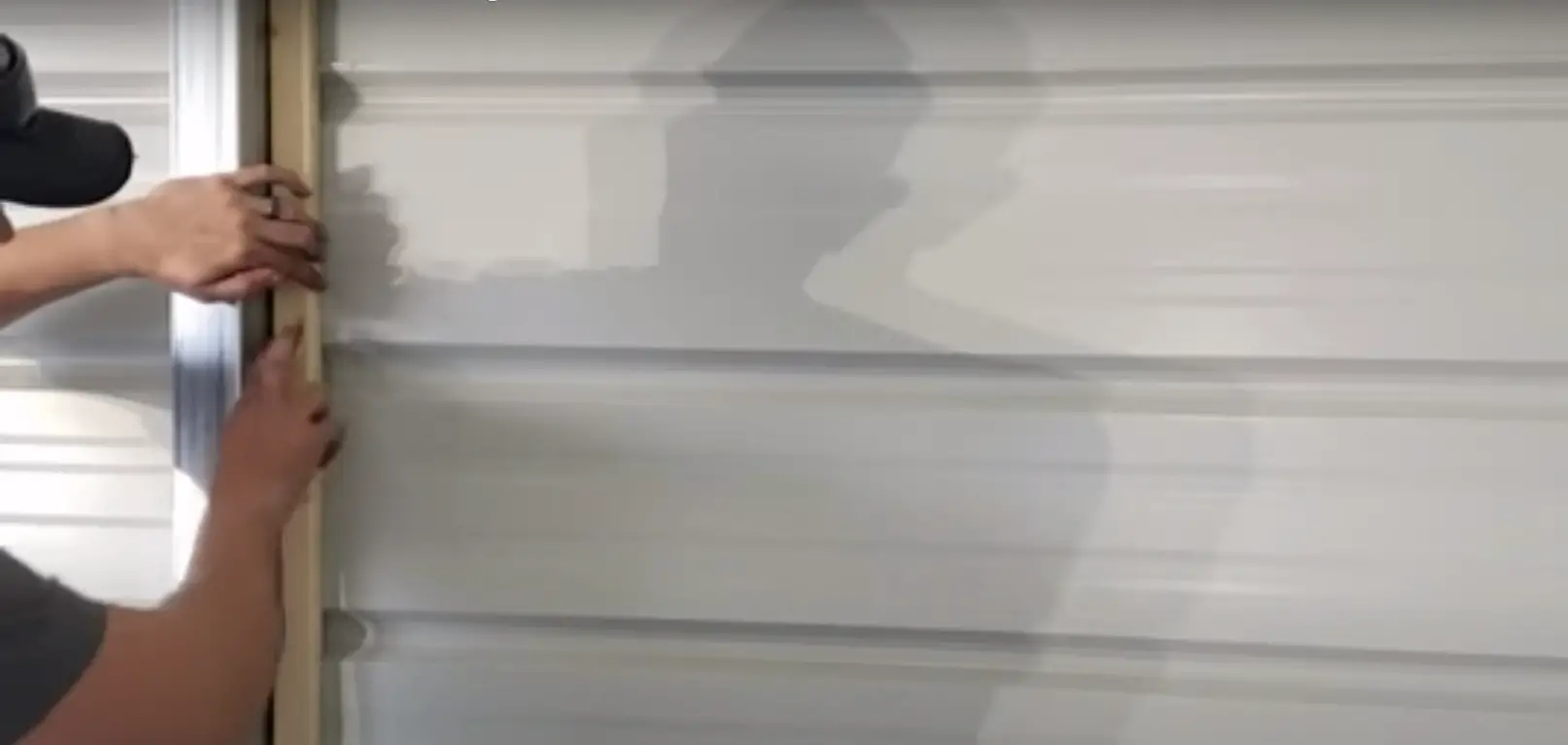

- Install the insulation – Start by cutting pieces of fiberglass batt to size and then lay them between the wall studs, using metal or plastic hangers or staples to secure them in place. Make sure all gaps are filled for maximum efficiency. If using foam boards, cut them to size and glue into place with a suitable adhesive. Spray foam can be applied directly onto walls and ceilings with a spray gun.

- Seal air leaks – Pay close attention to any cracks or holes in your shed’s exterior walls and seal these gaps with weatherstripping or caulk, depending on the size of the gap. This will help ensure that the shed retains heat during the winter and keeps cool air in during summer.

- Apply a vapor barrier – Finally, apply a vapor barrier over your insulation to keep moisture from damaging it. It should be applied with staples or adhesive before you install any wallboard or paneling onto the walls of your shed.

By following these easy steps, you can easily insulate your metal shed to make sure it remains comfortable all year round!

Benefits of Insulating a Shed

Insulating a metal shed has numerous advantages that can make storing items or working in the space much more comfortable. Insulation helps to regulate the temperature inside of your shed, meaning it won’t be too hot or too cold depending on the season. This also helps protect any valuables stored inside from extreme temperatures and humidity levels.

Lastly, insulation reduces the amount of energy needed to keep an area heated or cooled, resulting in lower utility bills for those who use their sheds throughout different seasons.

All these benefits make insulating your shed a great idea and well worth the effort. With proper insulation, you can enjoy a quiet, comfortable space all year round. Knowing how to properly insulate a metal shed is essential in order to reap these rewards. [7]

How Much Does It Cost to Insulate a Metal Shed?

Insulating a metal shed can be an expensive undertaking, depending on the size of the shed and the type of insulation you choose. Generally, you can expect to spend between $750 and $2,500 for a 10×12-foot shed. This cost is based on including labor costs as well as materials such as batt insulation, vapor barriers, and other supplies. You should also factor in additional costs like hiring a professional to do the work or renting tools if necessary. If you have time and skills to do-it-yourself, then it is possible to reduce your overall cost significantly by purchasing quality materials at discounted rates online or from local home improvement stores.

The best way to save money when insulating your metal shed is to use the right materials and make sure you install them properly. If done correctly, you can achieve a much higher R-value (the measure of thermal resistance) than with traditional fiberglass insulation. Rigid foam insulation panels are one of the most cost-effective solutions since they provide good insulation without any extra labor. The other option is spray foam insulation, which is great for covering small areas that otherwise would not be accessible with batt or rigid foam. However, this type of insulation tends to be more expensive while still requiring professional installation in order to guarantee results.

Can You Use Bubble Wrap Insulation in a Metal Shed?

Bubble wrap insulation is one of the most popular and cost-effective ways to insulate a metal shed. Not only does it provide an excellent thermal barrier against heat transfer, but it also provides an extra layer of protection from moisture, condensation, and even sound. Bubble wrap comes in sheets that can be easily cut to size for your specific shed dimensions, making installation simple and quick. With its easy application process, bubble wrap is one of the best options available for insulating a metal shed.

To properly install bubble wrap insulation on your metal shed, you will need to start by cleaning the surface area completely before applying the insulation.

Once the insulation has been properly installed, it is important to make sure it is airtight so that it can perform its job effectively. Check every corner and crevice for any gaps where warm or cool air might be escaping, and use caulk or sealant to create an airtight barrier. This will keep your metal shed insulated all year round, regardless of temperature fluctuations outside. With proper installation and maintenance, bubble wrap insulation can provide great energy savings in your metal shed for years to come! [8]

Is Spray Foam Good for Metal Sheds?

The short answer is yes, spray foam insulation is an effective option for metal sheds. Spray foam has a few key benefits that make it ideal for metal sheds: it’s easy to install, provides excellent air sealing and moisture control, and doesn’t require any additional materials or tools to use. Additionally, spray foam forms a tight seal around the edges of the shed to keep out moisture and pests.

However, there are some drawbacks to using spray foam in metal sheds. The biggest drawback is cost; due to its high R-value and air sealing capabilities, spray foam tends to be more expensive than other types of insulation. Additionally, if not applied correctly by an installer, the results may not meet your expectations.

If you’re looking for a cost-effective alternative to spray foam insulation, fiberglass or mineral wool batt insulation are both great options. Both types of insulation can be easily installed in metal sheds and provide good moisture control, but may not achieve the same air sealing properties as spray foam. As with any type of insulation, it’s important to read the manufacturer’s literature and follow the instructions carefully to ensure optimal results.

Finally, if you live in an area that experiences extreme temperatures or have an older metal shed, consider adding additional insulation layers such as reflective foil or rigid board panels. These materials will help regulate the temperature inside your shed and extend its lifespan by protecting against weathering and corrosion.

FAQ

What is the best insulation for a steel shed?

The best insulation for a steel shed is an insulation blanket made of either fiberglass or polystyrene foam. Fiberglass is the most popular choice because it is more affordable and easy to install, while polystyrene foam provides greater energy efficiency and better soundproofing. Both types of insulation will provide adequate protection from the elements, but if you are in an area with extreme temperatures, you may want to consider upgrading to a higher-grade product.

How do I insulate my metal shed?

Insulating your metal shed can be done in two ways: externally or internally. For external insulation, start by attaching an insulated panel system to the underside of your roof or walls. Then, use rigid foam boards to seal any gaps between the panels and the shed walls. For internal insulation, start by lining your interior walls with an insulation blanket like fiberglass or polystyrene foam. You can also add a vapor barrier to prevent moisture from accumulating in your shed. Finally, make sure to caulk any cracks or holes around windows and doors for additional protection from air leaks.

What materials do I need to insulate a metal shed?

To insulate your metal shed, you will need an insulated panel system, rigid foam boards, an insulation blanket such as fiberglass or polystyrene foam, a vapor barrier, and caulk. Additionally, you will also need basic tools such as a screwdriver and drill for installing these materials. Be sure to wear protective gear such as gloves, goggles, and a dust mask when cutting rigid foam boards or installing insulation.

Do insulated sheds get hot in the summer?

Insulated metal sheds do not generally get too hot in the summer if they are properly ventilated. However, if you live in an area with extreme heat, you may want to upgrade to a higher-grade product that provides better energy efficiency. Additionally, proper ventilation is key – make sure your shed has vents at both ends of the roof and consider adding additional fans or gables for improved air circulation.

What are the benefits of insulating my metal shed?

Insulating your metal shed will provide several benefits. The most obvious one is that it will help regulate the temperature inside your shed, keeping it cooler in the summer and warmer in the winter. Additionally, insulation can help keep out moisture, dust, and pests while also improving soundproofing. Finally, insulating your shed can significantly reduce energy costs over time.

How much does it cost to insulate a metal shed?

The cost of insulating a metal shed will vary depending on the size of your shed and the materials used for insulation. Generally speaking, you should expect to spend around $300-$500 for an average-sized shed using fiberglass insulation or $500-$1,000 if you choose foam panels. It’s always a good idea to get several quotes from contractors before making a decision so that you can get the best deal.

How do you attach insulation to metal?

The easiest way to attach insulation to a metal shed is with construction adhesive. This type of adhesive is specifically designed for use with materials like wood and metal, so it should create a strong bond that will keep the insulation in place. Before applying the adhesive, make sure that both surfaces are clean and free of dust or dirt. Then apply the adhesive to one surface and press the insulation firmly into place. Allow the adhesive to cure according to the manufacturer’s directions before continuing.

Useful Video: How To Insulate A Metal Building / Double Bubble Foil Insulation

Conclusion

Insulating a metal shed is an excellent way to make it fit for use during the winter months. Depending on the size of your shed, you may opt to insulate it with spray foam, rolled or batt insulation, or even rigid foam board. Make sure that all gaps and seams are properly sealed before adding insulation. Finally, if you have decided to go with spray foam insulation, avoid getting any on exposed metal surfaces as this can lead to condensation and rusting over time. If you follow these steps correctly, your metal shed will be warm and ready for use in no time!

Thanks for reading!

References:

- https://plasticinehouse.com/how-to-insulate-metal-shed/

- https://www.shelterlogic.com/knowledge/insulated-sheds-how-to

- https://www.gardenbuildingsdirect.co.uk/blog/metal-shed-insulation/

- https://alansfactoryoutlet.com/blog/how-to-insulate-metal-shed/

- https://www.gardenroom.guide/can-you-insulate-metal-shed/

- https://outdoorstorageoptions.com/how-to-insulate-a-metal-shed/

- https://howlongdoesrooflast.com/steps-on-how-to-insulate-a-metal-shed/

Leave a Reply

View Comments