The best way to protect the interior of your shed from weather and noise is to properly insulate it. Shed insulation improves air quality, adds comfort, reduces energy costs and increases the longevity of stored items. It can also help keep out insects as well as other critters which like to make a home in an uninsulated building! Insulation is most effective when applied to all four walls of a shed’s structure – including the floor. But how do you go about this? Have no fear – this blog post will walk you step-by-step through how to insulate a shed floor with ease!

Why Should You Insulate a Shed Floor?

Insulating a shed floor can have many advantages. It helps to keep the interior temperature of the shed more constant, thereby making it more comfortable for you to work in. Additionally, insulation keeps out humidity and prevents damage from moisture buildup, which is especially important if you plan on using your shed as a workshop or storage area.

Finally, insulation provides an extra layer of protection against critters and pests trying to gain access into your shed. All in all, insulating a shed floor is an effective way to protect your stored items and increase the overall comfort of the shed.

The process of insulating a shed floor will vary depending on the type of insulation material used, but generally involves measuring and cutting out panels or boards to fit the space. After this is done, it’s time to install them using screws, nails or adhesive depending on the type of material. When installing insulation, be sure to wear protective gear such as gloves and eye protection to prevent any injury or damage. [1]

Types of Insulation

Fiberglass

Fiberglass insulation is one of the most common types of insulation used in shed floors walls. It is made from recycled glass and comes in rolls, sheets, or pre-cut shapes. This type of insulation provides good thermal protection and offers some degree of soundproofing.

Spray Foam Insulation

Spray foam insulation can be applied to sheds using a spraying device that releases an aerosolized form of the material into the space between floor joists or walls. Unlike fiberglass insulation, it forms a sealing layer that discourages air leaks and keeps conditioned air inside the shed for better energy efficiency.

Foam Board Insulation

Foam board insulations are sheets made from expanded polystyrene (EPS), extruded polystyrene (XPS), or other rigid foam materials. They are easy to cut into any shape and size, making them suitable for projects of any complexity. This type of insulation provides good thermal protection and is often used in floors and walls to keep the shed interior warm and dry.

Vapor Barrier

A vapor barrier is a thin sheet of plastic that goes over the existing floor before adding any insulation material. Its purpose is to prevent moisture from seeping up into the insulation, which could cause mold buildup or structural damage. It should be applied on top of the subfloor before laying down fiberglass rolls, spray foam, or foam board insulation. [2]

Mineral Wool

Mineral wool insulation is made from basalt, a type of volcanic rock. It is available in batt form that easily fits between wall studs or joists and can be used for filling cavities around pipes and wiring. It offers excellent thermal protection and provides some degree of soundproofing as well. This type of insulation should be installed on top of the vapor barrier before adding any additional layers of insulation material.

How To Insulate a Shed Floor?

Adding insulation to the floor of your shed can help make it a more comfortable and energy-efficient space. It also helps protect stored items from any moisture that might seep into the shed, as well as reducing noise coming in or out of the structure.

Tools and Materials Needed:

- Insulation material – foam board insulation, fiberglass rolls, rigid foam boards, etc.

- Tape measure

- Utility knife

- Caulk gun

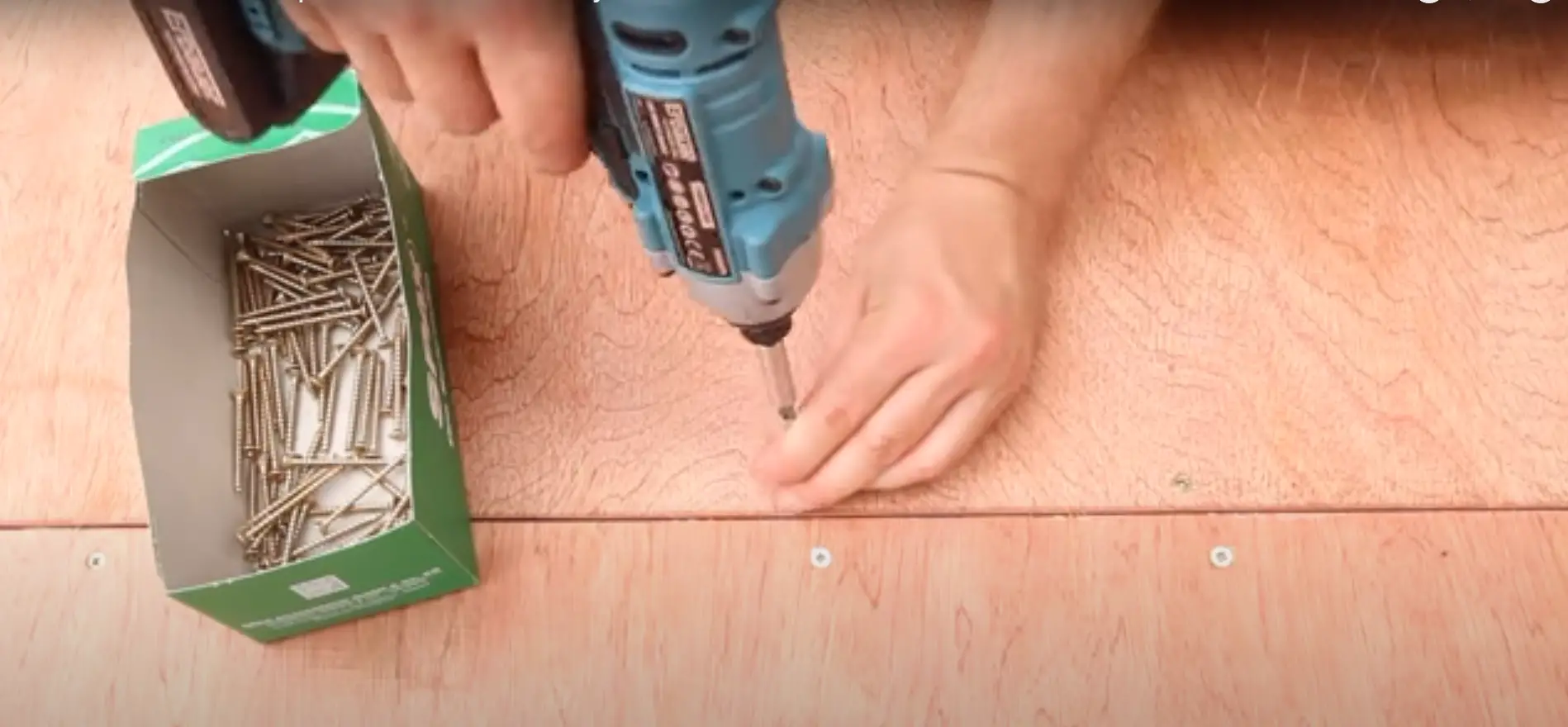

- Wood screws

- Foam adhesive (optional)

Instructions:

- Measure the area you need to insulate and purchase enough insulation to cover it. Make sure you account for any door openings or windows when measuring so you don’t end up with too much or too little insulation.

- Cut the insulation to fit your space, using a utility knife if necessary. If you are using foam board insulation, make sure to measure twice and cut once for an exact fit.

- Secure the insulation to the floor with wood screws or nails, making sure it is flush against the floor joists below. Alternatively, use a foam adhesive to hold the insulation in place if desired.

- Apply any seams between pieces of insulation with caulk or foam adhesive for an air-tight seal and improved energy efficiency.

- Once all the insulation has been laid down and secured, you’re ready to enjoy a more comfortable and efficient shed.

Now you know how to insulate the floor of your shed, you can start looking into other ways to improve your shed’s energy efficiency such as adding weather stripping and insulated doors or windows. [3]

Insulating a Pre-built Shed Floor

If you have a pre-built shed that is already set up, you may want to consider insulating the floor. This can help keep the temperature comfortable in your shed and also protect your stored items from moisture damage. Here are some tips for insulating a pre-built shed floor:

- Measure the dimensions of your shed’s interior and then purchase insulation boards according to those measurements. The most common type of insulation board available is expanded polystyrene foam (EPS). Before purchasing any materials, make sure you know exactly how much space needs to be insulated.

- Once you have your insulation boards, lay them down directly on top of the flooring surface. If there is any existing vapor barrier, be sure to remove it before laying down the insulation.

- Once you have laid down the insulation boards, use a utility knife to cut out any areas that don’t fit correctly. If there are any gaps between wall and floor panels, fill them in with spray foam or other suitable material.

- Cover the insulation boards with concrete backer board for added protection against moisture damage and temperature changes. This is especially important if your shed is located in an area susceptible to extreme temperatures or dampness.

- Apply a sealant around the edges of the backer board to ensure that no air can get through into your shed’s interior space. You can also add weather stripping along seams to further protect from drafts.

- Finally, lay down a layer of flooring material such as vinyl or tile to complete the insulation job and make your shed look great.

By following these steps, you can easily insulate a pre-built shed floor and protect its contents from moisture damage and extreme temperatures. It’s an easy project that anyone can do with a few simple tools! [4]

How to Insulate a Floor from the Top?

If you don’t have the option to insulate a shed floor from below, you can also insulate it from the top. To do this, first measure and mark out the area of the floor that needs to be insulated. Then cut pieces of insulation sheeting to match that size and fit them snugly into place on the underside of the shed’s roof. You may want to use adhesive tape or staples to keep them in place.

Make sure there are no gaps between insulation sheets so that air cannot pass through. After fitting all pieces of insulation, lay down your chosen flooring material on top; for instance, if you are using carpet tiles or vinyl planks. This will help to create an insulated barrier preventing temperature fluctuations inside the shed.

By following these steps, you will have successfully insulated your shed floor from the top. This will help to keep temperatures inside comfortable, as well as reducing noise levels from outside sources. Furthermore, it will also provide an extra layer of protection against moisture entering the shed and damaging items stored inside.

Other Methods for Installing from the Top

If you are looking for other ways to install insulation from the top, there are a few options available. One option is to use foam boards which can be directly applied on the underside of the roof. This method is often used in garages or sheds with metal roofs, as it provides excellent thermal protection without adding too much weight.

Finally, if you would prefer a professional to install your insulation, there are many companies who offer specialized services. These can be especially helpful in more complex installations such as those which require multiple layers of insulation; or ones with difficult access areas.

No matter what method you choose to insulate the shed floor, it is important to remember that proper installation is key to ensuring maximum energy efficiency and effectiveness. Therefore make sure to carefully read the instructions provided by your chosen material before commencing any project. This will help ensure that you get the most out of your insulation and enjoy comfortable temperatures inside all year round! [5]

How to Insulate a Shed Floor from the Bottom?

When it comes to insulating a shed floor from the bottom, there are several options. The most common option is to use rigid foam insulation boards. These boards come in different thicknesses and densities, allowing you to choose the best option for your particular project. You will need to make sure that the insulation board fits tightly between the joists of your floor and is secured with screws or nails so it doesn’t move around.

If your shed doesn’t have any joists, then you should consider installing some before laying down insulation boards. This will help provide additional support for your shed floor and prevent it from flexing or sagging over time. Once your joists are in place, you can secure the insulation board using construction adhesive.

Finally, you could also consider using fiberglass batting for extra insulation. This kind of insulation works great for providing additional warmth during cold months, but it requires more specialized tools and materials to install properly. It’s also important to make sure that any other surfaces around your shed are covered before installing fiberglass batting so that there is no chance of the insulation coming into contact with moisture or mold.

No matter which type of insulation you choose for your shed floor, it’s important to follow all safety precautions and manufacturer’s instructions when installing. This will help ensure that your shed stays warm and comfortable all year round. [6]

Alternatives to Tearing Up Floorboards

If tearing up the existing floorboards and installing a new insulation layer is not an option, there are other alternatives. One such measure is to use a foam board or rigid foam insulation material. These materials are designed to fit snugly between the floor joists of your shed and then sealed against moisture with caulk, tape or weather-resistant sealants.

The advantage of using this type of insulation is that you don’t need to disturb the existing flooring, yet still achieve heat retention benefits. In addition, it’s relatively easy to install and can be cut with a utility knife into whatever size you need for each joist gap.

Lastly, these types of insulation products come in various thicknesses so you can choose whichever best suits your needs. Some are better suited for smaller, contained areas while thicker ones can provide more protection against heat loss.

Overall, insulating your shed floor is a good idea if you want to retain heat and reduce energy costs – whether you use rigid foam board insulation or traditional fiberglass batt insulation underneath the floorboards, either will make sure your shed stays temperature-controlled throughout the year!

Can the Climate Impact a Shed?

Yes, the climate can have an effect on a shed. Depending on where you live and what temperatures are common in your area, it is important to consider the need for insulation when constructing or renovating a shed floor. In areas with hot and humid climates, insulation will help keep the temperature inside the shed more comfortable by preventing warm air from getting trapped within its walls.

Similarly, in colder climates insulation will be necessary to prevent cold air from entering the shed and causing damage to any items stored inside of it.

Additionally, if you plan on spending time working or relaxing in your shed throughout all seasons, then insulating it properly can make that experience much more enjoyable as well. If you live in an extremely cold climate, such as one with heavy snowfall, you may even want to consider installing a heating system for your shed in order to create a comfortable space year-round.

What Is the R Value of the Insulation Needed?

The R value of the insulation you need for a shed floor depends on a variety of factors, such as the climate where you live and how much heating or cooling your shed will be subjected to. Generally speaking, an R-value between 11 and 19 is recommended for most climates in the United States. However, if your shed will be exposed to extreme temperatures, it’s best to get an even higher R-value rating for maximum energy efficiency.

Additionally, some types of insulation materials have better insulating properties than others, so make sure you take this into account when deciding which type to buy. For example, fiberglass insulation has an R-value of 3.2 per inch while spray foam can have up to 6 per inch. Research the different types of insulation materials available to decide which one is best for your shed.

Finally, always remember to wear protective gear when handling insulation and installing it in your shed. Gloves, goggles, long sleeves, and proper footwear are all important pieces of safety equipment that can help protect you from an accident while working on your project. Once you’ve taken all these factors into account, you should be able to find the right insulation for your shed floor. [7]

FAQ

What is the best way to insulate a shed floor?

The best way to insulate a shed floor is by using a combination of insulation materials, such as rigid foam boards and fiberglass batting. This will provide an effective barrier against heat loss and help keep the shed warmer in colder climates. It is also important to use a vapor barrier or other waterproofing material when installing insulation, as this will help protect against moisture damage and mold growth. Additionally, it is important to ensure that any gaps between the insulation panels are sealed with caulking or expanding foam sealant. This will prevent air from entering around the edges of the panels and allow for better energy efficiency overall.

Is it necessary to insulate a shed floor?

Insulating a shed floor may not be necessary depending on its intended use and climate. However, insulating the floor will have several benefits, such as keeping the shed significantly warmer in cold climates, reducing costs for heating or air conditioning and helping to reduce condensation that can lead to mold growth. Additionally, some insulation materials can also help reduce noise from outside sources.

Are there any special considerations when insulating a shed floor?

When installing insulation in a shed floor, it is important to make sure that all edges are properly sealed with caulking or expanding foam sealant. This will help ensure that no air is entering around the edges of the insulation panels and allow for better overall energy efficiency. Additionally, it is important to use a vapor barrier or other waterproofing material when installing insulation since this will help protect against moisture damage and mold growth. It is also important to ensure that the insulation materials are correctly sized to fit the dimensions of the shed, as an improper fit can lead to heat loss and inefficiencies.

What are some common insulation materials used for shed floors?

Common insulation materials used for shed floors typically include rigid foam boards and fiberglass batting, although there may be other options depending on the size and climate of the shed. Rigid foam boards provide a strong barrier against heat loss while also providing additional structural support. Fiberglass batting helps fill any gaps between panels of rigid foam boards while still providing good thermal insulation properties. Additionally, reflective foil barriers can be added which further increase energy efficiency by reflecting back some of the heat generated by the shed.

Is it worth insulating the shed floor?

Yes, it is worth investing in insulation for your shed floor. Insulating the shed floor can help to reduce heat loss and air leakage from the inside of the shed to the outside. It can also provide some soundproofing qualities and even act as a moisture barrier which will help to prevent damp from forming in the shed walls or floor. Additionally, insulating the floor can improve comfort levels in your shed if you use it for any extended period of time.

Do I need a Vapour barrier when insulating a shed?

Yes, you will need to include a vapor barrier when insulating your shed. The vapor barrier acts as an additional layer of protection and helps to prevent moisture from entering the walls or floor of your shed. It is important to make sure that you choose a vapor barrier which is specifically designed for use in sheds and other outdoor structures, such as polyethylene sheeting. Additionally, it is recommended that the vapor barrier is installed on the inside of your shed walls and floor before any insulation material is added. This will help ensure that any moisture that enters the structure can be contained within the vapor barrier and not cause damage to any insulation material which may be present.

Useful Video: Garden Room Workshop: Part 6. Insulation & Plywood floor

Conclusion

Insulating a shed floor is an important part of creating a comfortable and safe work environment. Adding insulation to the walls and ceiling can help maintain consistent temperatures during hot or cold months, while adding additional soundproofing materials can help reduce noise pollution. Additionally, laying down waterproof material or plastic sheeting over the insulation can protect it from moisture damage while providing additional levels of comfort and safety. With proper planning and installation, you’ll be able to create a comfortable and enjoyable workspace in your shed for years to come.

References:

- https://plasticinehouse.com/how-to-insulate-shed-floor/

- https://www.gardenbuildingsdirect.co.uk/resource/insulate-a-shed-floor/

- https://leahday.com/pages/insulating-a-prebuilt-shed-floor

- https://www.buildingmaterials.co.uk/info-hub/insulation/how-to-insulate-a-shed

- https://shedsforhome.com/how-to-insulate-a-shed-floor/

- https://everyinside.com/how-to-insulate-a-shed-floor/

- https://www.acesheds.co.uk/blog/how-to-insulate-a-shed-floor

Leave a Reply

View Comments